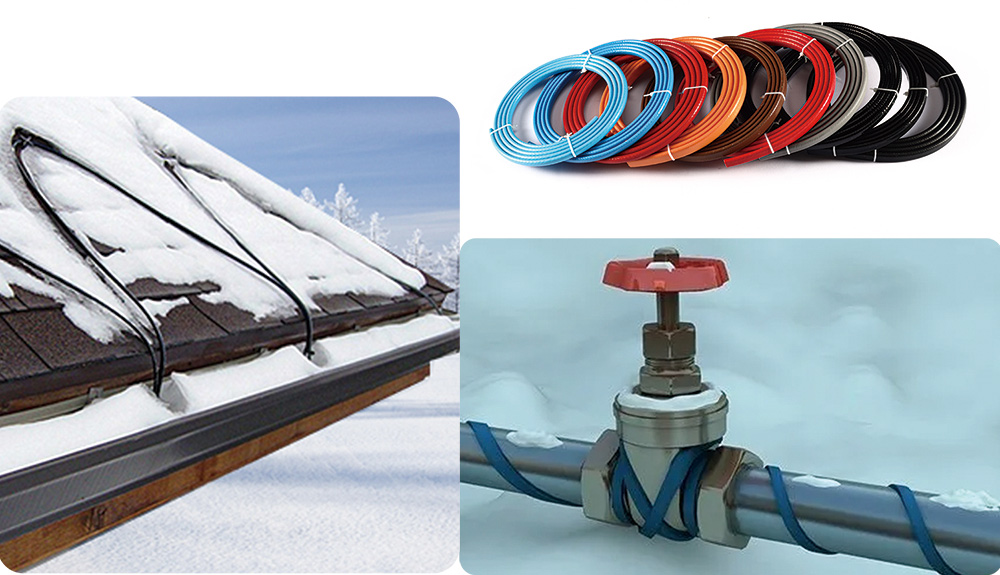

SRM Anti-freezing Self Regulating Heat Cable Water Pipe Freeze Protection

Supply voltage :

220V-240VNominal power :

10W/m, 15W/m, 20W/mMaximum Un-energized temperature :

85°CMaximum Energized temperature :

65°CMinimum installation temperature :

-40°C1. 0.5m㎡ copper conductors

2. Self-regulating conductive core

3. Thernoplastic insulation

4. Tinned copper braid

5. Fluoroplymer outer jacket(CF)/Thermoplastic outerjacket(CT)

Technical Data:

| SRM Series | Output Power@+10°C(W/m) | Max length@0°C | Max length@-20°C 16/20A(m) | Size (mm) | Weight((kg/km) |

| 10SRM2-CT | 10w/m | 128 | 124/128 | 7.9*5.6 | 71 |

| 10SRM2-CF | 10w/m | 128 | 124/128 | 7.9*5.6 | 71 |

| 15SRM2-CT | 15w/m | 102 | 88/102 | 7.9*5.6 | 71 |

| 10SRM2-CF | 15w/m | 102 | 88/102 | 7.9*5.6 | 71 |

| 20SRM2-CT | 20w/m | 90 | 70/74 | 7.9*5.6 | 71 |

| 10SRM2-CF | 20w/m | 90 | 70/74 | 7.9*5.6 | 71 |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)